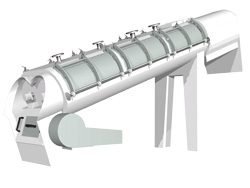

CTIS/CTID mash thermal conditioner and pellet mill or extruder super conditioner

CTIS/CTID mash thermal conditioner and pellet mill or extruder super conditioner

- Anti-salmonella bacteriological treatment

- To make high flowability feeds

- High nutrition efficiency due to increased digestibility

- Higher level of liquid absorption

- Moisture content control

Product is through steam injection heat treated within the inclined and heated conditioning chamber including one or two rotors.

When used as per super conditioner in front of pellet mill or extruder :

- Monitored resident time from 1 to 3 minutes

- Product temperature up to 85 degrees

- Pelletizing and crumbling energy costs significantly reduced

RCCS-TF dryer cooler

The RCCS-TF cooler has been especially designed for cooleing heat treated meals. It is also suitable for pellets cooling

The resident time is accurately monitored with full emptying of the chamber.

The top floor is used for drying, including an heater air inlet. Others 2 floors are cooling stages and connected to a hygienic treated inlet air from outside.

The meal stay onto each floor for an adjusted resident time according the throughput rate of the process. It is moved through special rotating arms and fluidised through raising up air flows.