Process selection criteria

Process selection criteria

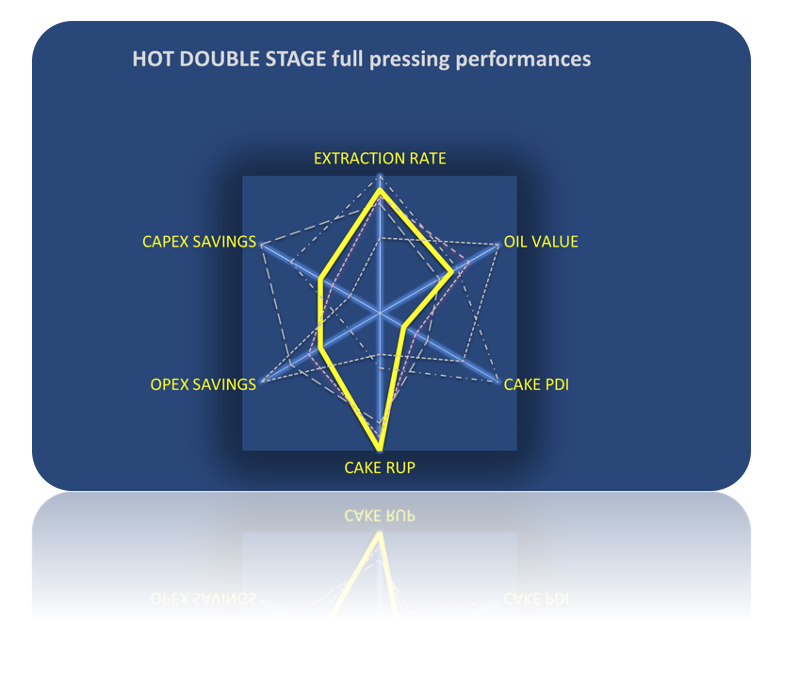

Selection of the right process route for Full Pressing is based on several criteria, related to both the economics (CAPEX and OPEX analysis, products YIELDS) and the specificity of the products (CAKE and OIL).

The key market reason to select Hot Double stage full pressing is to produce, at lower operating cost, a good quality cake with high protein content and high RUP (Rumen Undegradable Protein) content, and to reach a high oil extraction rate. The RUP, or by-pass protein, are not digested by rumen bacteria and are, therefore, available for further digestion and absorption by the animal small intestine. It is of utmost importance for dairy cow milk productivity. The hot double stage process is recommended to maximize Oil Yield when processing high oil content (30% or more) seeds, typically sunflower or canola.

Other selection criteria are:

Oil Value: The very good oil extraction rate makes the hot double pressing suitable in most cases when oil yield is priority. Hot double pressing will give the greatest and the most consistent oil yield across varying feed materials. However, due to cooking, some nutritional components of the oil may be affected or degraded. For best oil quality, see Cold Single Stage Full Pressing.

Cake value: As a result of double pressing, residual oil in cake is typically lower than 8% and protein content relatively high. Protein is partially denatured during the cooking and the two stages pressing does affect the PDI quite significantly (however no more so than for solvent extracted meals). The meal will have an increased RUP content and be most suitable to ruminant feeds. If higher PDI meal is desired with lower residual oil, then consider Extrusion + Full Press.

OPEX Saving: The benefit of double pressing is the good oil yield. However, due to double cooking and pressing step, the Hot Double Stage Full Pressing has a relatively high consumption of electricity and steam. For lower utilities consumption, see Hot Single Stage.

relatively high cost of investment. It remains, however, a good alternative to the solvent extraction plant when regulations (environmental, safety…) or funding are limiting factors. For lower CAPEX, see Hot Single Stage Full Pressing.

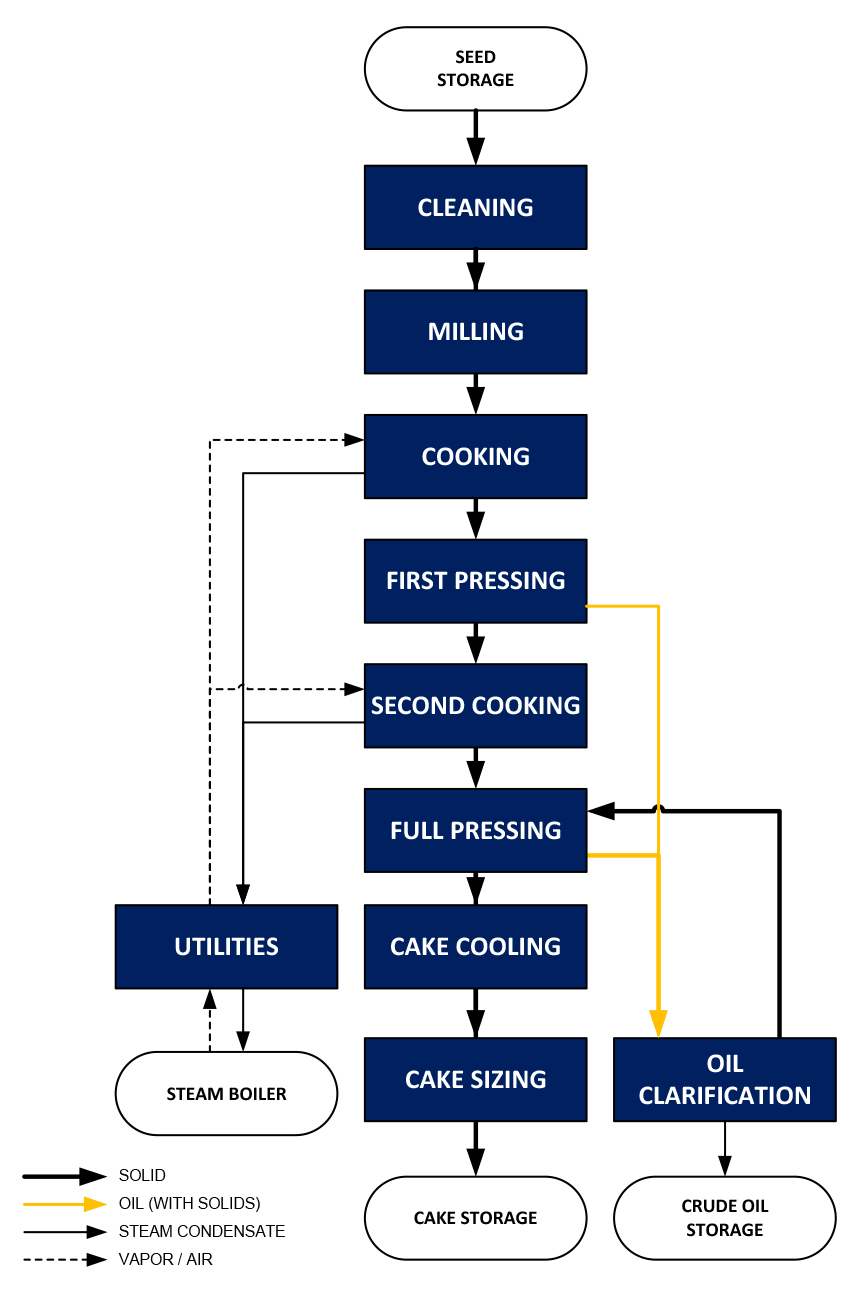

Process configuration

The seed from storage may contain up to 2% foreign material. The purpose of the cleaning process is to remove as much of foreign material as possible. An optional weighing process can be foreseen to get an accurate inventory of the material being sent through the seed preparation process.

Milling is aimed at reducing inlet raw material into smaller size particles to reduce the work done in the Press. For smaller and softer feed materials, Milling may not be required ahead of the pre-pressing stage. When Milling is required, it may be achieved in a hammer mill, or cracking rolls. In some cases, the milling can be combined with dehulling system, generally aimed at increasing protein content on the press cake.

The Cake after prepressing should be broken or milled to increase the heat transfer rate in the subsequent cooking process. Depending on the feed material this Milling may be sufficient using a cake breaker built into the Pres Press but on certain feeds it may be achieved in a hammer mill, or cracking rolls.

First cooking is a thermal process which heats the inlet material to approximately 100ºC (212F) and reduces its moisture to about 4%. It is aimed at turning hard and harsh cracks/flakes into soft and easy to squeeze material, and at same time, increase friction, thereby pressure, on the material inside the press resulting in oil extraction rate increase. DesmetBallestra offers full range of horizontal and vertical cookers design.

First Pressing can also be considered a pre-pressing, typically to recover easily available oil. Properly prepared and pre-cooked material is fed continuously into the screw press where cellular structure of the seed is severely distorted, tearing open many of the cell walls. Roughly 50 to 70% of the seed oil content will be extracted while producing a cake with an oil content about 20%, ideal for downstream cooking and second pressing. DesmetBallestra offers a full range of ROSEDOWNS screw presses with specific arrangement for pre-pressing, for all kind of seeds, all capacities.

First Pressing can also be considered a pre-pressing, typically to recover easily available oil. Properly prepared and pre-cooked material is fed continuously into the screw press where cellular structure of the seed is severely distorted, tearing open many of the cell walls. Roughly 50 to 70% of the seed oil content will be extracted while producing a cake with an oil content about 20%, ideal for downstream cooking and second pressing. DesmetBallestra offers a full range of ROSEDOWNS screw presses with specific arrangement for pre-pressing, for all kind of seeds, all capacities.

Second Cooking is a thermal process which heats the press feed material to approximately 110ºC (230F) by indirect steam contact. It is aimed at both reducing the moisture down to 3% range and to increase the fluidization and availability of oil. Both parameters will guarantee the highest oil reclaim from the squeezing of the material into the press. DesmetBallestra offers full range of horizontal and vertical cookers design.

Second Pressing also called full pressing. The pre-pressed cake with a typical residual oil in cake about 20% is fed continuously into the screw press where the cellular structure of the seed is further distorted, tearing open many of the remaining cell walls. Most of the oil in the pre-pressed cake will be extracted while producing a full-pressed cake with both integrity of shape and porosity, ideal for downstream cake cooling. DesmetBallestra offers a full range of ROSEDOWNS screw presses with specific arrangement for full pressing, for all kind of seeds, all the capacities.

Cake cooling is needed to remove excess of heat from the cake coming out of the press. Cooling is achieved through convective and evaporative heat transfer from cake to air passing through the cake layer on a fully counter-current flow. After the Cake Cooler, the cooled cake has a temperature within the range of 20 to 40°C (68 - 104ºF), and a moisture contains below 3%.

Oil clarification is required as it is inevitable that there will be a level of residual solids in the extracted Press oils. In hot/hot press plant, oil coming from first and second press steps can be clarified on same clarification system.

The Oil clarification is a two-step process that separates solid matter from the Press oil. The first separation step removes most coarse solids by screening or settling. Then, a second separation step removes the small fines and impurities from the oil by filtration using a hermetic leaf filter or, in large plants, by a centrifugal decanter.