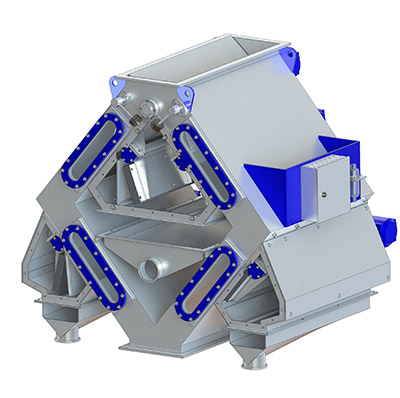

Metallic impurities removal at its best in preparation process

Desmet Magnetic Separators provide reliable and economical removal of ferrous contaminants from product flows in gravity-fed chutes. They are ideal for separating various sizes of foreign fines to larger pieces of tramp iron in numerous industries, including food, feed, grain, plastics, and chemicals.

Desmet Magnetic Separators provide reliable and economical removal of ferrous contaminants from product flows in gravity-fed chutes. They are ideal for separating various sizes of foreign fines to larger pieces of tramp iron in numerous industries, including food, feed, grain, plastics, and chemicals.

Seeds or grains entering the separator are forced to change direction passing over the upper magnetic plate where the first removal of ferrous impurities is accomplished. As the material slows down, it again changes direction and passes over a second lower plate magnet for final cleaning. This ‘dogleg’ design takes advantage of the ferrous metal density as the heavier metallic debris are more likely to work their way down to the magnet, increasing the probability of capture. The double parallel cascade design allows automatic cleaning operation whithout interrupting the flow of material.

Main Features

- Maximum separation effect with double pass over the magnetic plates.

- Automatic changeover for cleaning operation without process flow interruption.

- Powerful Rare Earth magnetic material.

- Self cleaning design.

- Dust-tight casing construction in reinforced Carbon Steel folded plates (optional Stainless Steel).

- Replaceable wearing resistant protection on parts in contact with the material and diverting flap.

- Ample Plexiglass inspection windows.

- Electro-pneumatic valves, manifold and filterregulator and accessories in attached dust proof cabinet.

- Easy access removable covers for inspection and maintenance.

- Profibus connection with PLC.