Here is how the LMTM works

Here is how the LMTM works

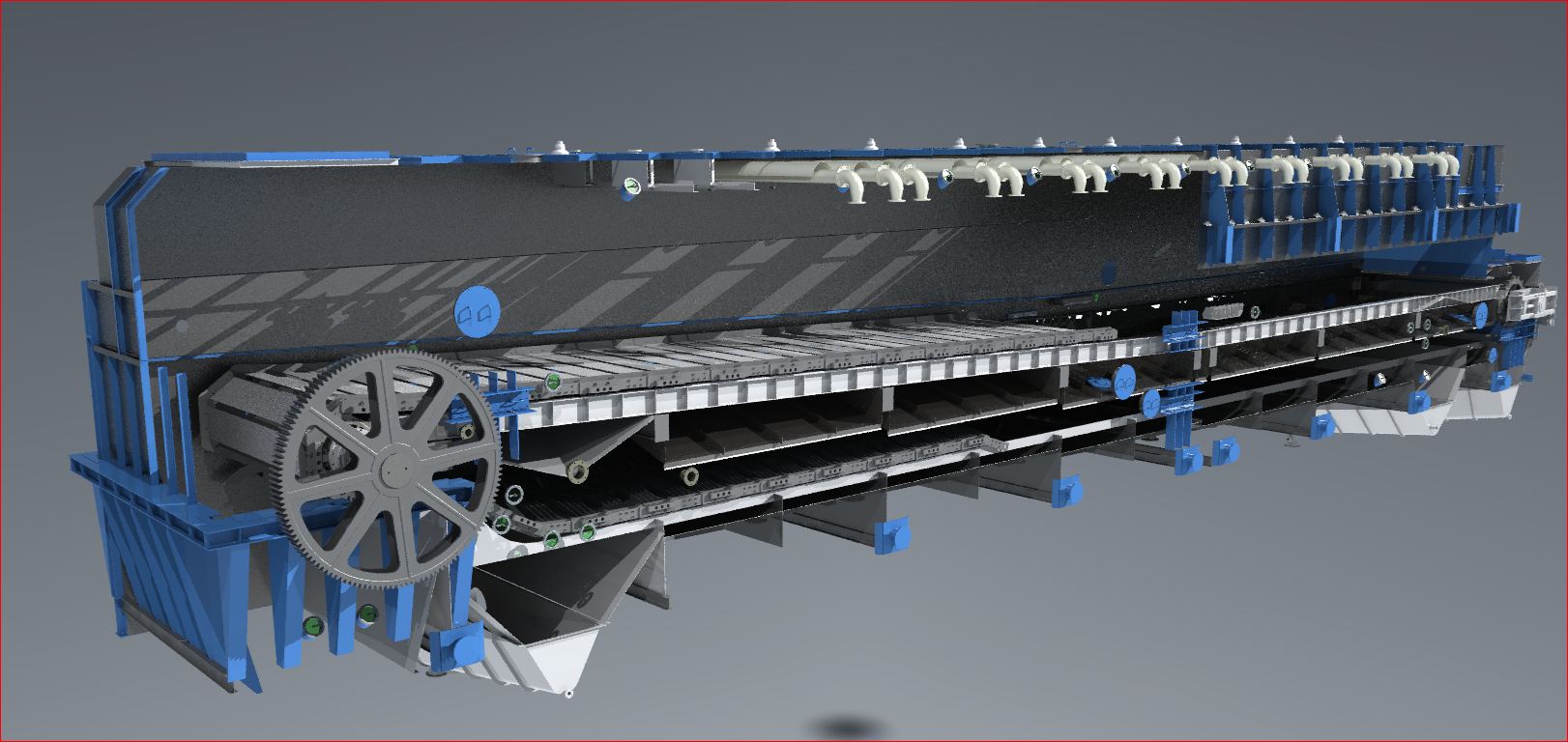

Material enters through an inlet hopper and is soon saturated with miscella - extraction starts immediately after entry.

After the initial saturation, the bed of material is continuously washed with counter-current stages of miscella.

Rakes at the surface of the material bed, along with an upward belt slope, maintain percolation and prevent miscella contamination.

Since the miscella has more contact time to penetrate the flake than in shallow bed designs, thicker flakes can be used to achieve

desired residual oil.

Maximum Material - Miscella Contact

Contact time is the single most important factor for the efficient solvent extraction of vegetable oils.

To maximise contact time, the LMTM ’s initial immersion sequence enables the oilseed material to be completely surrounded with miscella.

This is followed by a long percolation sequence to keep the miscella stages separated and extract the remaining oil.

The simplicity of the LMTM extractor design delivers the reliability you need to gain the competitive edge.The LMTM is the essence

of reliability and simplicity – a rectangular housing enclosing a slow moving belt, driven by a single head shaft.

Mechanical design advantages

Mechanical design advantages

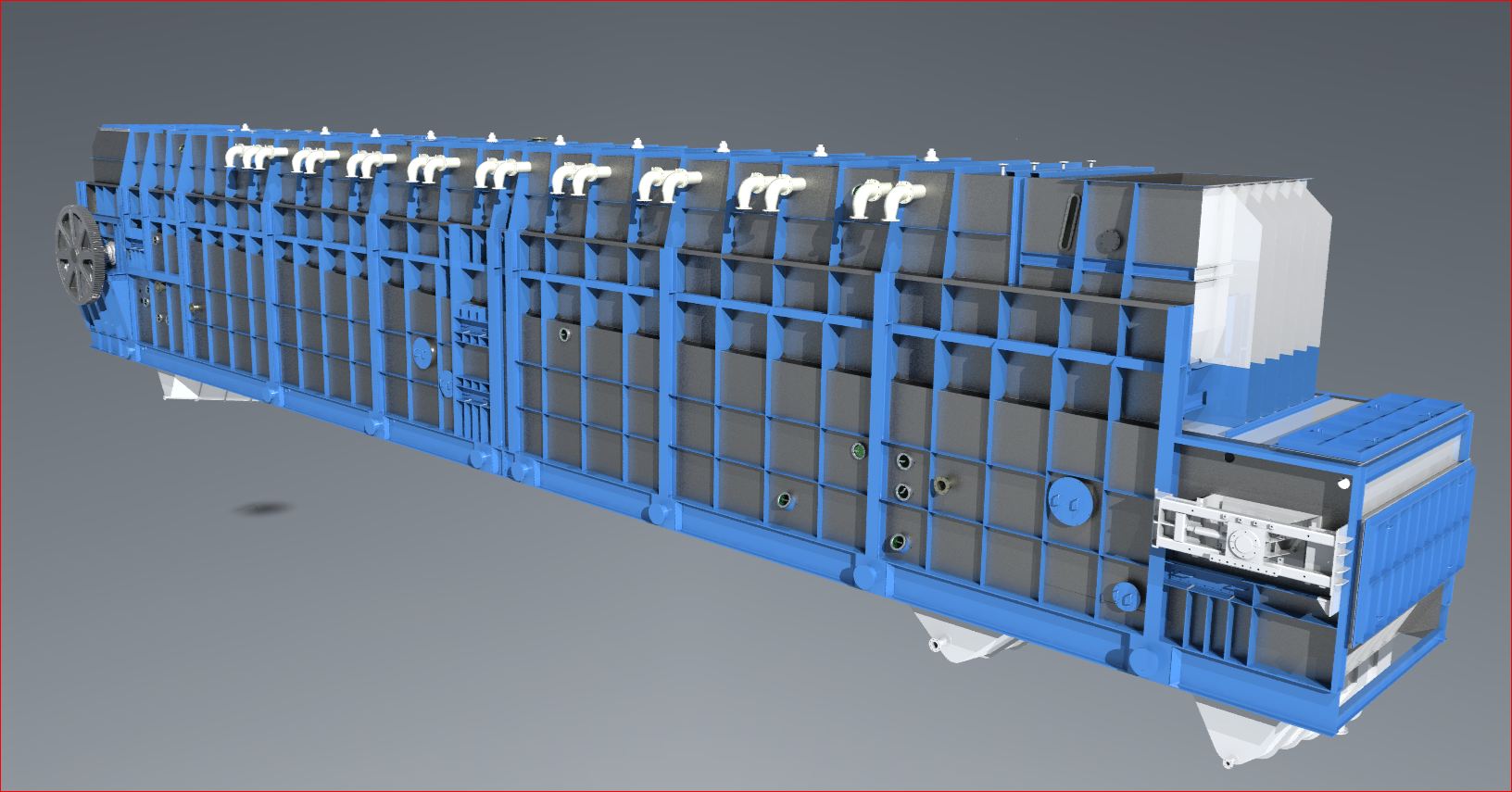

Reinforced strength in construction with standard corrosion-resistant casing.

Pre-assembly for rapid and low cost installation requiring the minimum of site works.

Inclined bed ensures true counter-current operations under any conditions.

Stainless steel, self cleaning wedge bar or mesh screen for different rawmaterials.

Low maintenance and ease of operation emphasis:

- Exterior access to mechanical parts

- Improved, easely mounted drive/hollow shaft gearbox

- Special, long life conveyor chain.

- Auto control with uniform discharge